Why Choose Us

Founded in 2006, YAC Chemicals Limited is a wholly-owned subsidiary of LATOP Group and specializes in the overseas business, and sells aerosols to more than 46 countries in the world.

Latop Group focuses on the R&D, production, and sales of aerosol products, and is currently one of the leading companies in China's aerosol cosmetics industry.

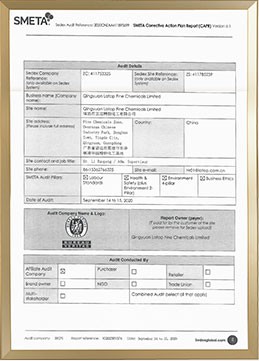

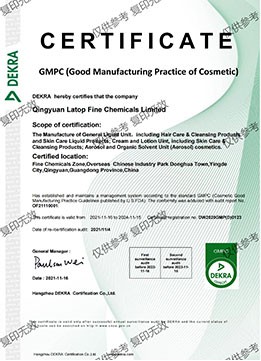

We were awarded one of the "TOP 100 OEM cosmetics manufacturers in China" and audited by Walmart, BSCI, WCA, CTI, SCAN, and SMETA 4P., also gained the FDA, GMPC, and ISO22716 certifications.

-

01

Have 1000+ MATURE formulas applied for mass production

-

02

Accept customized sampling /package /formulas /fragrances

-

03

More than 17 years experience in manufacturing and developing

-

04

Has a quality management system that meets and exceeds industry standards-18KE

Certifications

Automatic production Line

-

Fully sealed canning guarantees the integrity of the material liquid, preventing external contamination. This method ensures that the purity of the liquid is maintained throughout its storage and transportation. Hermetically sealing the containers minimizes the risk of any impurities or foreign particles entering the liquid. This approach is crucial in preserving the quality and safety of the liquid for its intended use.

-

Automation of the production process means that it is completely computer-controlled from the time raw materials are added to the product filling tanks until the finished product is produced. The operator only needs to supply auxiliary ingredients and keep an eye on the production process.

-

9 high-speed automatic filling production lines 2 high-speed binary aerosol filling production lines The whole line realizes automatic weighing, automatic 50-degree constant temperature water bath, and automatic plastic sealing. The annual production capacity exceeds 80 million pieces.

R&D New Products

Our independent and more powerful cosmetics professional R&D team uses cutting-edge skin biological engineering, plant extraction and separation, detection analysis, and other techniques as the basis for modern scientific theory, forming the raw materials for cosmetics, formula application, finished product safety and efficacy evaluations, and research on clinical testing and other aspects, offering the theoretical foundation and real scientific basis for the formulation of cosmetics.

Independent quality management department

Every week, supervisors check the production room's sanitary index requirements; if the test results are subpar, production will stop until the problem is fixed. strictly in compliance with GMPC and ISO22716 requirements. To guarantee that the product is a safe and high-quality production, expert personnel closely controls every step of the production process, from the acceptance of incoming material to the finished product inspection.

Assay And Test

Regarding the use of raw materials and product formulas, as well as all aspects of product development, including testing, ingredient analysis, and qualitative, quantitative, and other types of analysis.